Machines need to relay critical information to their immediate environment quickly and reliably. The data displays efficiently fulfil the requirements to be fulfilled by these systems:

- high visibility;

- 24×7 availability;

- variable digit colour (green, amber, red), depending on the behaviour of the value displayed, showing the status of the data displayed quickly and clearly;

- protection levels to suit the setting;

- capacity to display numeric and text information.

Lartet has been designing and manufacturing displays since 1986. It offers a very comprehensive range of devices for the industrial environment that adapt to the needs of machinery manufacturers.

Displays for machines

The Lartet industrial displays deliver all the characteristics required for integration in complex machinery.

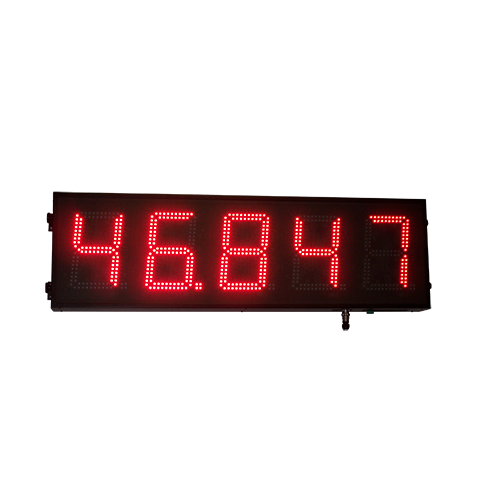

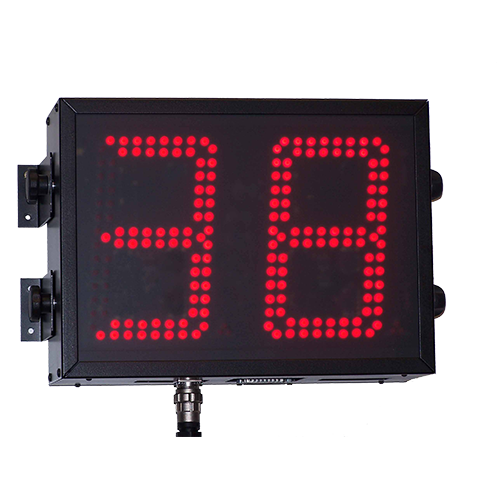

- High visibility; digit height from 30 mm to 250 mm, thus guaranteeing perfect readability from up to 120 m. Models with high-brightness digits.

- Digits on 1, 2 and up to 4 faces, making the data displayed visible from any angle and minimising the number of displays to be installed.

- Large information display capacity. Text displays of up to 8 lines with a maximum number of 26 characters on each. Numeric displays of up to 10 digits.

- Immediate integration with any data bus, thanks to multiple network connection options. Bus connection to Siemens, Omron and Rockwell PLCs. Adaptation to specific protocols.

- Great number of analog and digital inputs.

- Chained messages with time and date variables or with operator-defined variables.

- Protection from particles in suspension (IP54, IP65).

- Conditional digit colour depending on user pre-established values.

- Up to 2 relays to activate external devices.

- Possibility of showing the units of the variables displayed with LED digits or with text printed on vinyl.

- In some models, easy configuration, administration and communication through the web server integrated in the display.

Functions:

- part counter;

- cycle time;

- indicators for temperature, pressure, process speed, power, voltage, and vibration;

- rejection rates;

- timer, tachograph;

- indicators for operating instructions integrated in the company’s ERP system;

- integration with SCADA systems;

- machine status indicators;

- safety instruction displays.